Galvanized Wire Mesh is a versatile, corrosion-resistant solution for multiple uses, including fencing, animal enclosures, and construction reinforcement. Its galvanized coating ensures durability and longevity, making it suitable for both indoor and outdoor applications. Easy to install and maintain, this wire mesh provides reliable protection and structural support for various projects.

Galvanized wire mesh, just like ss hardware cloth, has become an indispensable tool in modern agriculture due to its versatility and durability. One innovative use is in crop protection. Farmers use galvanized wire mesh to create protective enclosures around crops, safeguarding them from pests and animals without the need for harmful chemicals. This eco-friendly solution ensures healthier produce and reduces environmental impact.

Another application is in livestock management,which is also a crucial application of chicken hardware cloth. Galvanized wire mesh is used to construct sturdy and secure animal enclosures, providing a safe environment for livestock while preventing escapes and predator attacks. Its corrosion-resistant properties make it ideal for outdoor use, ensuring longevity and minimal maintenance.

Additionally, galvanized wire mesh is employed in soil erosion control. By reinforcing soil with mesh, farmers can prevent erosion on slopes and riverbanks, promoting sustainable land use. This method is particularly beneficial in areas prone to heavy rainfall.

Overall, the innovative uses of galvanized wire mesh, in agriculture enhance productivity, sustainability, and animal welfare, making it a valuable asset for modern farming practices.

Regular Cleaning: Periodically clean your galvanized wire mesh with mild soap and water to remove dirt and debris. This prevents buildup that can lead to corrosion over time.

Inspect for Damage: Regularly inspect the mesh for signs of wear, rust, or damage. Promptly repair or replace any compromised sections to maintain structural integrity and effectiveness.

Protective Coating: Apply a protective coating or paint to the mesh to enhance its corrosion resistance. This is especially important in harsh environments or areas with high humidity.

Proper Storage: Store unused galvanized wire mesh in a dry, covered area to prevent exposure to moisture and contaminants. Proper storage extends the lifespan and maintains the quality of the mesh.

1. Galvanized welded wire mesh

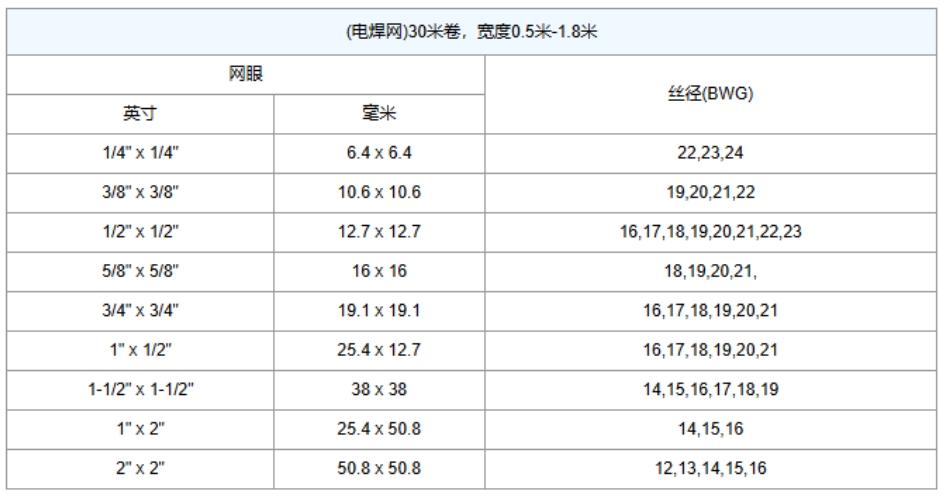

1. Common specifications:

Surface treatment: electrogalvanizing, hot-dip galvanizing (hot-dip galvanizing has better corrosion resistance)

2. Main uses:

Construction engineering: used for wall reinforcement, ground crack prevention, and support materials for concrete pouring.

Animal husbandry: making animal fences, chicken cages, rabbit cages, pig pens, etc.

Agricultural field: used for crop protection, greenhouse frames and grid structures.

Industrial applications: machinery protective covers, shelves, and handicraft frames.

Civil decoration: used for indoor and outdoor wall decoration and gardening protection.

2. Stainless steel welded wire mesh

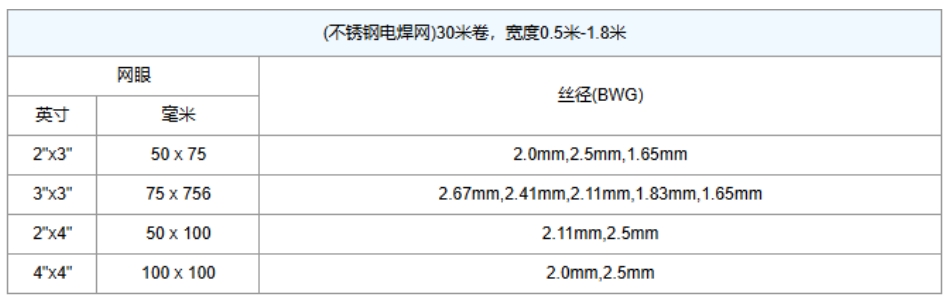

1. Common specifications:

Material:

Common models: 304, 316, 316L stainless steel (304 is a common material, 316 has stronger corrosion resistance)

Surface: no need for galvanizing, with natural corrosion resistance

2. Main uses:

Food industry: making food trays, baking nets, oven partitions, etc., in line with food grade safety standards. Chemical industry: used for filter nets and safety protection nets in acid and alkali environments.

Petroleum industry: used for oil well sand control nets and protective isolation layers.

Medical field: used for brackets, screening nets and protective nets for medical equipment.

Building decoration: high-end building facades, guardrails, staircase protection nets.

Marine engineering: strong corrosion resistance, suitable for humid and seawater environments.

Summary of the difference between the two:

Corrosion resistance: Stainless steel welded mesh is better than galvanized welded mesh, especially suitable for high humidity or acid and alkali environments.

Price: The price of galvanized welded mesh is lower, and the price of stainless steel welded mesh is higher.

Service life: Stainless steel welded mesh has a longer service life, followed by hot-dip galvanized welded mesh.

Application range: Stainless steel mesh is suitable for high-demand industrial, food, and medical fields, and galvanized mesh is more used in general construction and agricultural fields.

If you encounter any problems while browsing, please feel free to contact us at any time. We provide you with 7×24 service. In case of emergency, please contact us via email: sales@wiremeshprovider.com